Engineering Compliance.

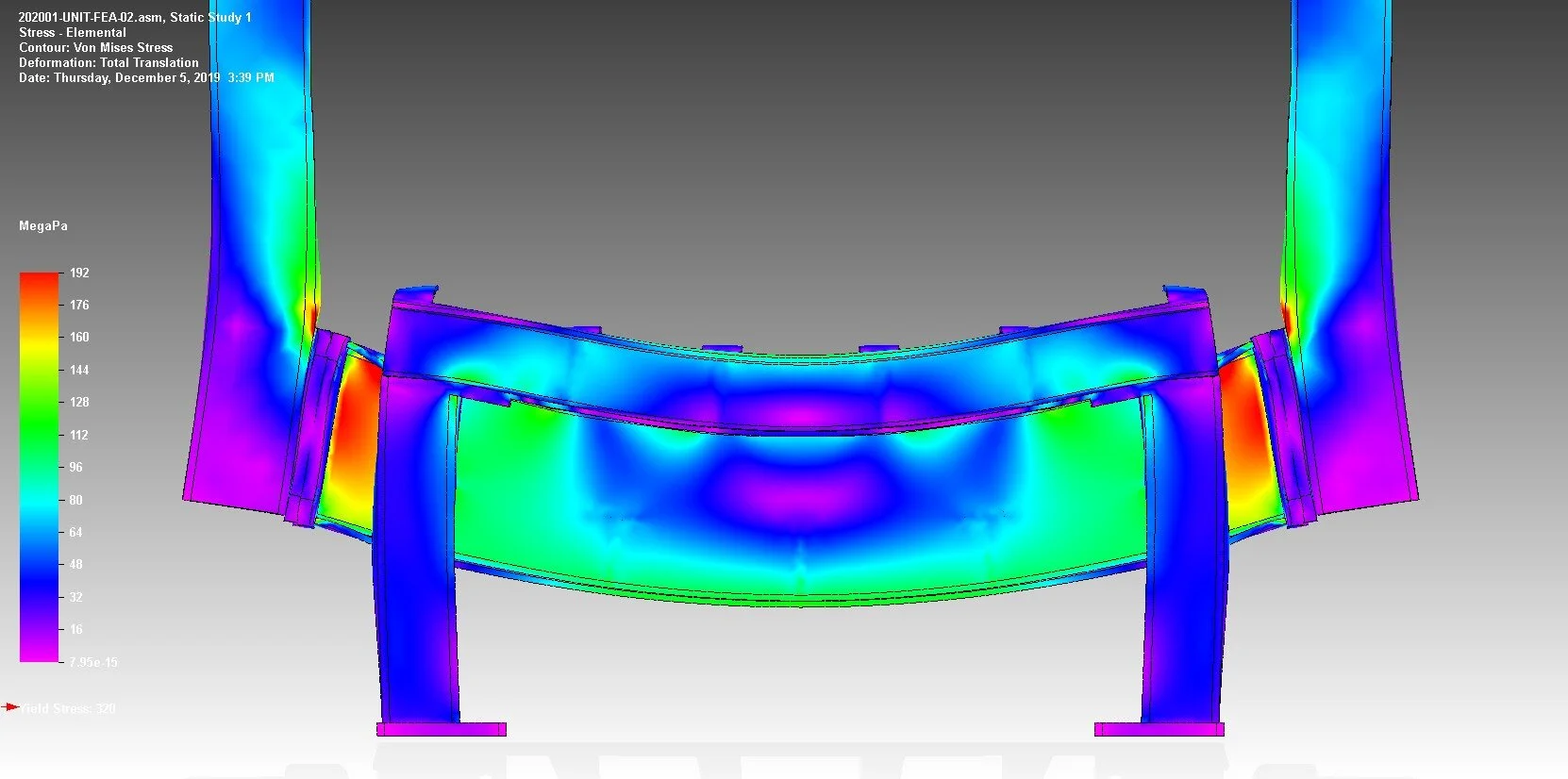

Using a suite of analysis tools such as FEA, SpaceGass, and Strand7, Trang Imagineering can provide Standards Compliance on mechanical devices, and verify that they are both structurally adequate, as well as compliant to safety and other performance requirements.

Engineering compliance and verifications are essential processes in the field of engineering that ensure that designs, systems, or products meet specified requirements, standards, regulations, and quality criteria. Let's understand each term individually:

Engineering compliance refers to the adherence of engineering designs, processes, or products to applicable standards, regulations, codes, or guidelines. These can include industry-specific standards, international standards, safety regulations, environmental regulations, building codes, and more. Engineering compliance ensures that engineering practices and products meet the required legal, safety, and performance standards.

Engineering verification is the process of confirming that a design, system, or product meets the specified requirements, performance criteria, or design intent. Verification ensures that the engineering solution functions as intended and fulfills the desired objectives. Engineering verification involves various activities such as testing, analysis, simulations, inspections, and reviews to validate the design against the established criteria. It may also involve comparing the actual performance or behavior of the system or product against the expected outcomes.

The compliance and verification processes are crucial for ensuring that engineering designs and products are safe, reliable, and meet the desired standards. They involve rigorous testing, analysis, and documentation to provide evidence that the engineering solution complies with the applicable regulations and functions as intended. By conducting compliance checks and verification activities, engineers can minimize risks, ensure quality, and build trust in the engineering work they deliver.