3D Laser Scanning.

Trang Imagineering provides 3D Laser Scanning services for measuring and modelling internal and external surfaces for mechanical plant & equipment such as: Buckets; Process Piping; Tanks; Vessels and Structural Steel.

3D laser scanning is a technology that captures the spatial information of objects or environments by using laser beams. It is a non-contact, non-destructive method that allows for the creation of highly detailed and accurate 3D models of real-world objects or scenes.

Overview of the Laser Scanning Process:

3D laser scanner emits laser beams in a sweeping motion across the target object or scene. These laser beams bounce off the surfaces they encounter, and the scanner records the time it takes for the laser to travel back to the scanner. By measuring the time-of-flight of the laser beam, the scanner calculates the distance between the scanner and the object's surface, generating a dense point cloud of 3D coordinates.

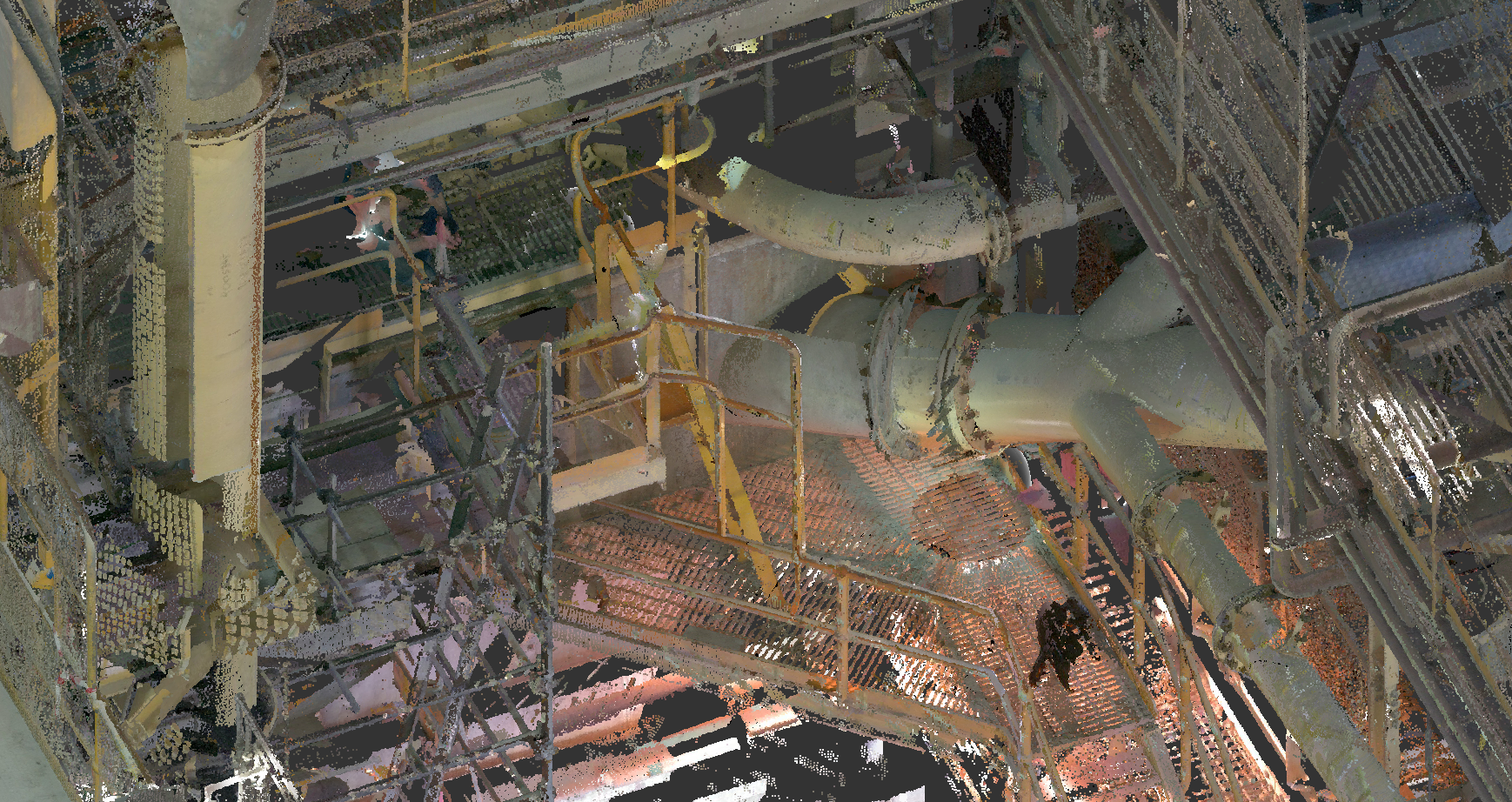

The laser scanner collects millions of data points during the scanning process, creating a point cloud—a large set of 3D coordinates that represent the surface geometry of the scanned object or scene. Each point in the point cloud corresponds to a specific location on the object's surface.

Once the point cloud is generated, it undergoes further processing to remove noise, outliers, and unwanted data points. Data registration techniques align multiple point clouds if scanning is performed from different positions or angles. The processed point cloud is then used to create a digital 3D model.

The point cloud data is converted into a digital 3D model using specialized software. The software analyzes the point cloud, reconstructs the surface geometry, and creates a digital representation of the scanned object or scene. This model can be further edited, refined, and exported in various formats for visualization, analysis, or integration into other design or engineering workflows.

3D laser scanning provides a highly efficient and accurate method for capturing detailed 3D information, enabling improved visualization, analysis, and documentation of real-world objects and environments.

Laser scanning creates a comprehensive data capture of geometry that can be utilised for: reverse engineering dimensions of existing equipment; designing new equipment into an existing plant; and measuring volumes.

The scan data captured is used in with our internal CAD software, for designing the required solution.

Based in Orange NSW, we are ideally located to service Western NSW.